The OpenSpace technology meets Graham’s “Innovation with Purpose” standard.

Gaining accurate real-time insight into a construction project’s progress, comparing the site situation to plan and seeing that problems are rectified have been long-sought goals – always with decidedly imperfect solutions. A recently applied technology is enabling construction providers to take large steps in the right direction.

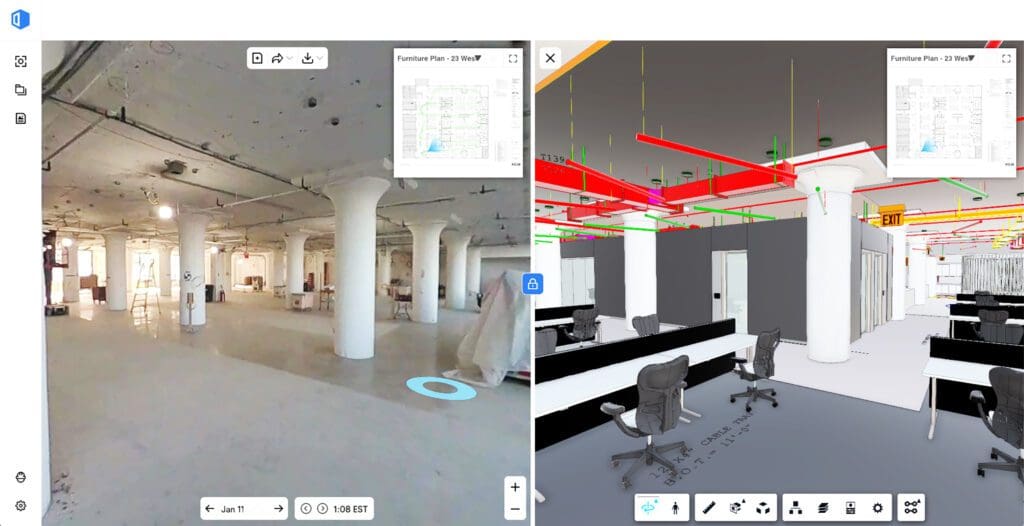

OpenSpace records 360-degree helmet-cam views, shooting one still image per second that, when run through the firm’s software, builds an “immersive reality” that simulates moving around a site – indoors or out. The data reside on a website accessible to authorized users. When mated with AI and LiDAR, OpenSpace provides a 4D (three dimensions over time) progress map, letting the contractor’s personnel, subcontractors and clients to visually track progress week by week, confirm work done, make notes and assign tasks.

OpenSpace capture & 3D model rendering of OpenSpace capture

The OpenSpace technology meets Graham’s “Innovation with Purpose” standard by which the company separates gimmicks and distractions from genuine advancements that improve the company’s efficiency and benefit clients.

“The increased site transparency is so much better than the old way of doing things,” says Brent Stratton, an Engineer-in-Training at Graham and the company’s Toolbox Next Generation Stream 5 Lead.

“The add-on functions create a lot of further value. Project owners love being able to easily track things.”

Stratton piloted OpenSpace on the Aria Project, a 288-suite complex in Calgary financed by Gracorp, Graham’s development arm. “We commenced regular 3D capture walks outside for the site plan and inside for the main level plans,” Stratton recalls. “We compared the actual pictures with the 3D construction model, how things were lining up, where the finishes went, and so on.” Weekly shoots facilitate efficient tracking of construction progress, comparison to schedule and identification of deficiencies. Side-by-side comparisons of successive recordings, notes Stratton, allowed “everyone to see the whole building progressing.

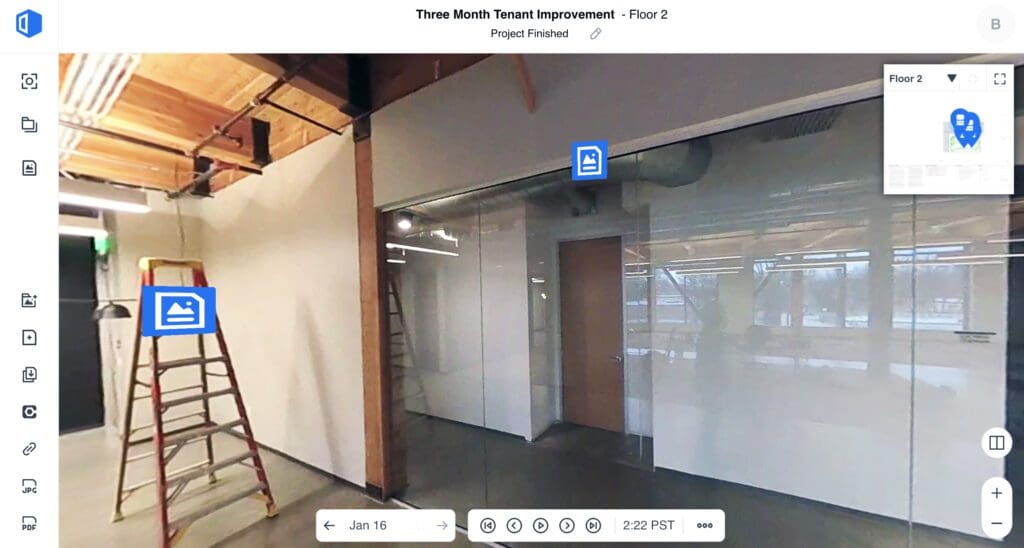

”Numerous real-world benefits flow from the use of OpenSpace. The system incorporates meta-data that include all users and their area of responsibility. Users can take field notes and embed icons on the imagery that, in turn, can be used in deficiency reports and assignment of remedial tasks. Safety personnel can inspect a site virtually and either confirm requirements are being met or highlight areas of concern. Users can also query specific features – “fire alarms”, for example – and the software will match all corresponding items, allowing comparison to plan and thereby making quality assurance more efficient.

OpenSpace capture with associated field notes

On a practical level, if it becomes necessary to inspect hidden infrastructure like valves, for example, the precise location facilitated by OpenSpace imagery minimizes the physical destruction needed for access. At times, it can avoid physical work altogether. On one Graham project, the digital record of a buried waterline’s installation satisfied a government inspector that the company had included the required automatic shut-off valve, avoiding what would normally have been time-consuming and costly re-excavation.

Stratton foresees the benefits of OpenSpace extending past construction. “You can see when the exterior and interior’s various layers went in,” he explains. “So if there’s a concern later that something was missed, you can go back and confirm that everything was done to plan.” For the same reason, Stratton expects OpenSpace to be handy on future renovations and upgrades by providing a quick and accurate review of the as-built environment.

In addition to being better than the old way, the costs and complexity of any innovation should be less than what it replaces. Inexpensive, easy to use and flexible, OpenSpace clearly meets these tests for application in the construction industry.

Innovation with Purpose

Graham is continuing its journey of adopting innovative tools and processes, and implementing technological solutions that increase value, improve efficiency for our clients and make things easier for our on-site project teams. We are thoughtful in our adopting and implementation of innovative technological tools and processes – we will not move forward with something simply because it’s interesting or unique. Our path of innovation is underpinned by the value/benefit each solution yields. Innovation with purpose.